Vickers Hardness Tester – V-TEST II

Vickers Hardness Tester – V-TEST II

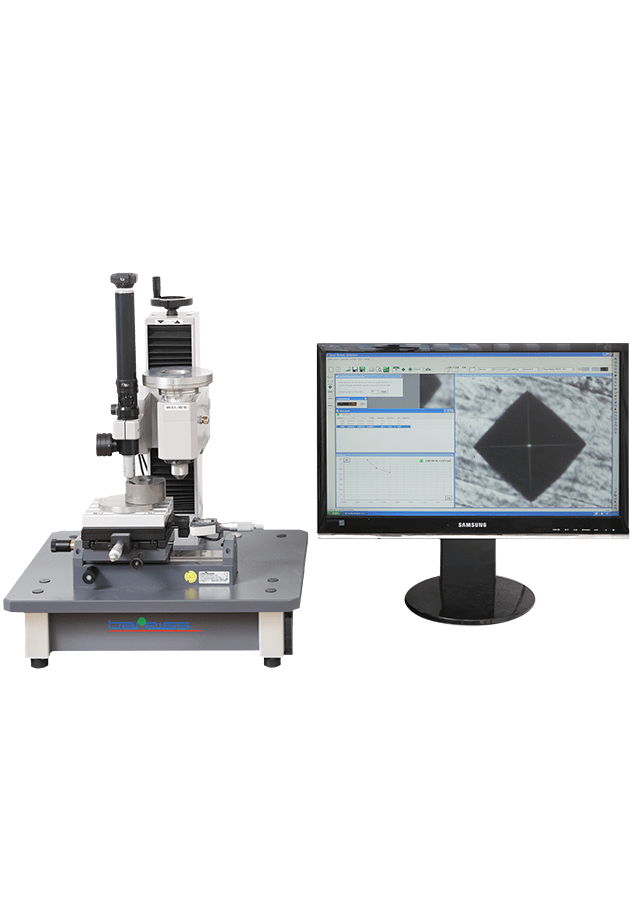

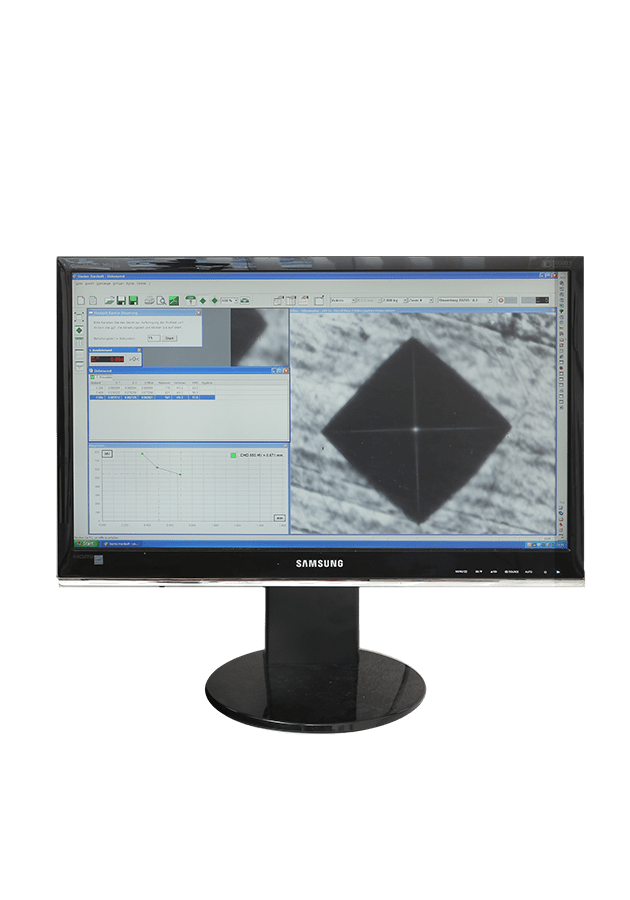

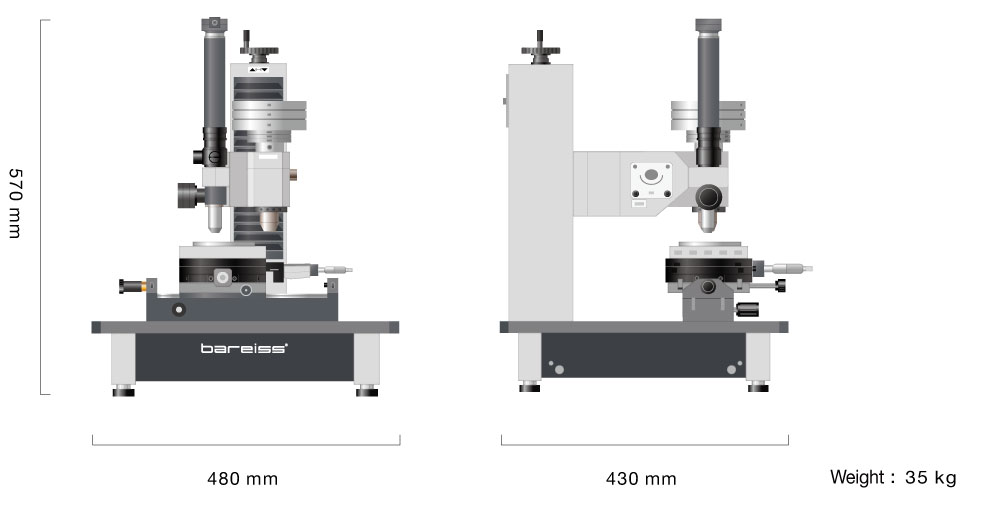

V-Test II Vickers Hardness Tester: For hardness determination on metals and ceramics. The basic set-up includes manually positioned Z-axis on test stand, manually positioned X-axis table magnetic supporting table O 100 mm. The black and white camera has digital optics with zoom micro objective and 20 times magnification including illumination – other options of objectives are available.

DAkkS/DKD Calibration Certificate

DAkkS/DKD Calibration Certificate