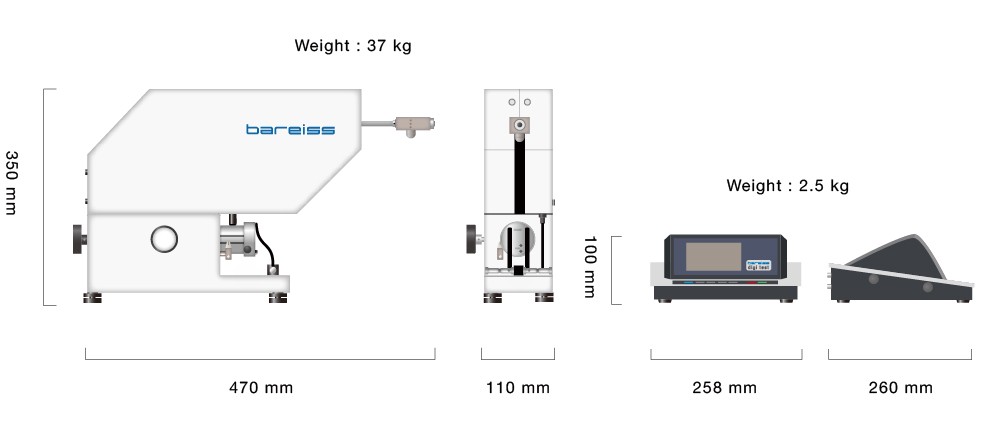

Features: Our rebound resilience tester offers a range of features that make it the go-to choice for reliable and accurate testing.

1) With our optional temperature control module, you can easily perform measurements under varying temperature conditions, gaining critical insights into material behavior. Our guided pendulum movement ensures precise and repeatable results by self-checking the swinging time of the pendulum hammer.

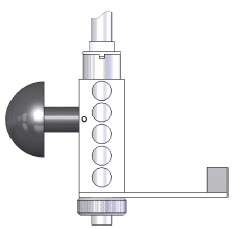

2) Our flexible spring clamp system allows for easy clamping of various specimen samples up to 50mm thick, streamlining your testing process. Retrieve your results with ease using our external electronic unit featuring an illuminated display.

3) The Rebound Resilience Tester also features an automated test sequence, automatically detecting samples against idling and damage to the anvil plate. And for added convenience, our optional clamping device provides a reliable 200N force to fix your test specimen in place.

Experience the ultimate in testing capabilities with the Rebound Resilience Tester.

Operating Procedure: The Rebound Resilience Tester is designed with ease-of-use in mind, allowing you to perform reliable and accurate measurements with just a few simple steps.

1) Simply switch on the electronic unit and select your desired measurement configuration according to standards. The unit displays Mode 1 acc to standards, and you can confirm by pressing Ok on the electronic unit.

2) The measurement is then activated, and our guided pendulum movement drops the pendulum six times from the horizontal position to the same place on the specimen. The pendulum is then caught or stopped, repeating the impact procedure to test the resilience of your material.

3) For even more precise results, our tester performs three mechanical pre-conditioning impacts before measuring and displaying the resilience for the fourth, fifth, and sixth impacts. The median value is then calculated for added accuracy.

4) Need to perform measurements under specific temperature conditions? Our optional tempering module allows for measurements at temperatures of up to 100°C, while also performing mechanical preconditioning for reliable results.

5) And for added flexibility, our electronic unit also includes a control function to measure friction control. Simply read the measured value on the display and listen for a signal sound to inform you of the end of the control procedure. Note down the number of oscillations and time taken to determine if the control was successful.

Experience the ultimate in testing capabilities with the Rebound Resilience Tester – the go-to choice for accurate and reliable material elasticity measurements.