Operating Procedure

Measuring devices Shore, A, B,0, D, C, D0, 00, 000, 000S, Asker C, CS:

1) The electronic unit is switched on and using devices for shore D, C, D0, Asker CS the display shows: Apply additional weights and the loads are applied accordingly.

2) The sample is placed onto the supporting table so that there is proper contact between the surface of the supporting table and the sample.

3) Results are more reliable and precise when the highest point of the sample is below the indenter.

4) The supporting table is moved by hand wheel so that the distance between the indenter and the test specimen is 3mm

5) Press the ‘START’ key and the measuring device is automatically lowered onto the test specimen.

6) Once the measuring time is completed the measuring device moves back to its starting position and the measured value is shown on the display and the data can be transmitted simultaneously.

Measuring device Shore, A/B/0:

1) The loading weight on this measuring device should be in a free-moving position. If it’s fixed in the upper position, push up and rotate against the arrow direction.

2) Care must be taken to check that the indenter is not visible during testing as the loading weight must be movable freely.

Measuring device M Shore, A/B/0, M Shore D:

1) The knurled screw is loosened until the loading weight can be moved freely.

2) Care must be taken to check that the indenter is not visible during testing as the loading weight must be movable freely.

Measuring device M Shore, A/B/0, M Shore D:

1) The knurled screw of the pressure plate must be loosened so that the pressure plate can be moved freely.

2) Care must be taken to check that the indenter is not visible during testing as the pressure plate must be movable freely.

Product features and benefits

1) User-Friendly: This automatic shore hardness tester is equipped with an electronic unit that can show user information, time, and method of measurement, and is equipped with various other configurations along with automatic measurement of time and range detection.

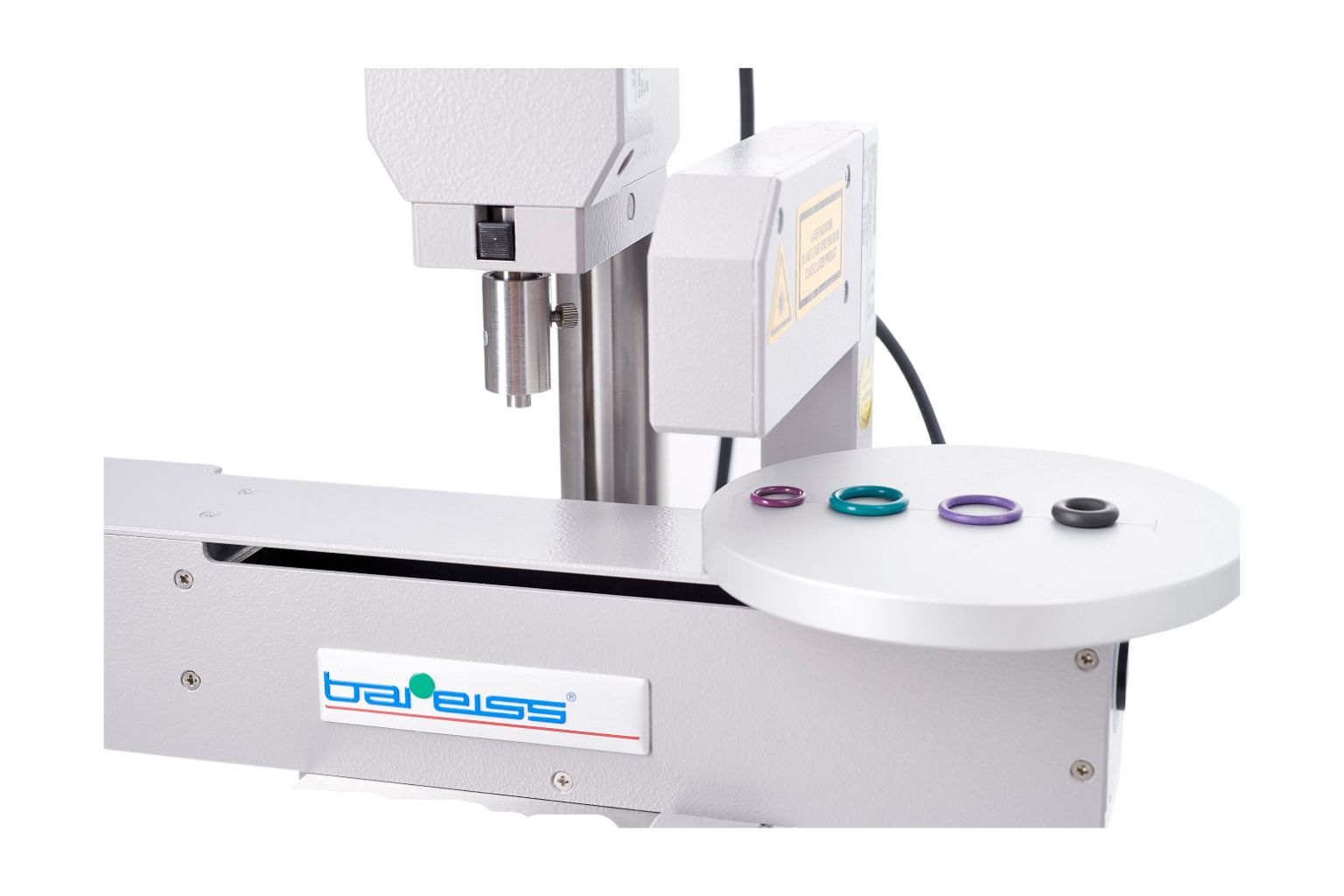

2) Range of Measurement: This Automatic hardness testing machine can measure the hardness of O rings, seals, rubbers, and plastics by making use of special measuring devices for which the fixtures can also be customized according to the sample that is to be tested.

3) Mechanism: The measuring devices have an easy plug-and-play solution with no complex mechanism. The measuring devices can easily be fastened by hand using the knurled nut and the electronic unit can easily detect the device once it is set up.

4) Complexity: Concave and convex samples can easily be tested for their shore hardness using the special measuring devices developed by Bareiss.

5) Special Features: The hysteresis function is available in Micro, IRHD and VLRH methods, providing a better understanding of the results for further analysis.

7) Integrable in an automatic production process.