Product Information:

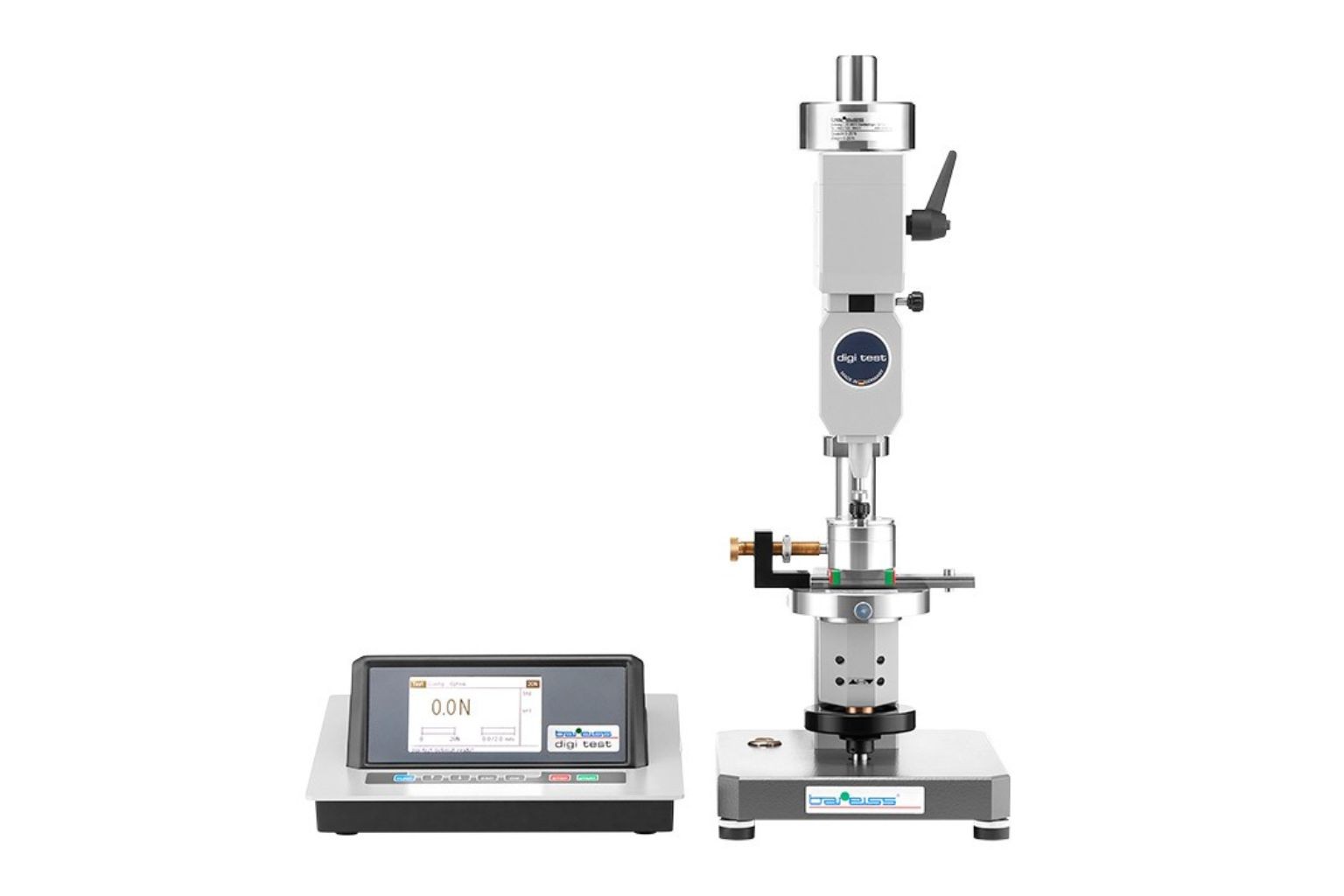

Capsule Hardness Tester – digi test II Gelomat

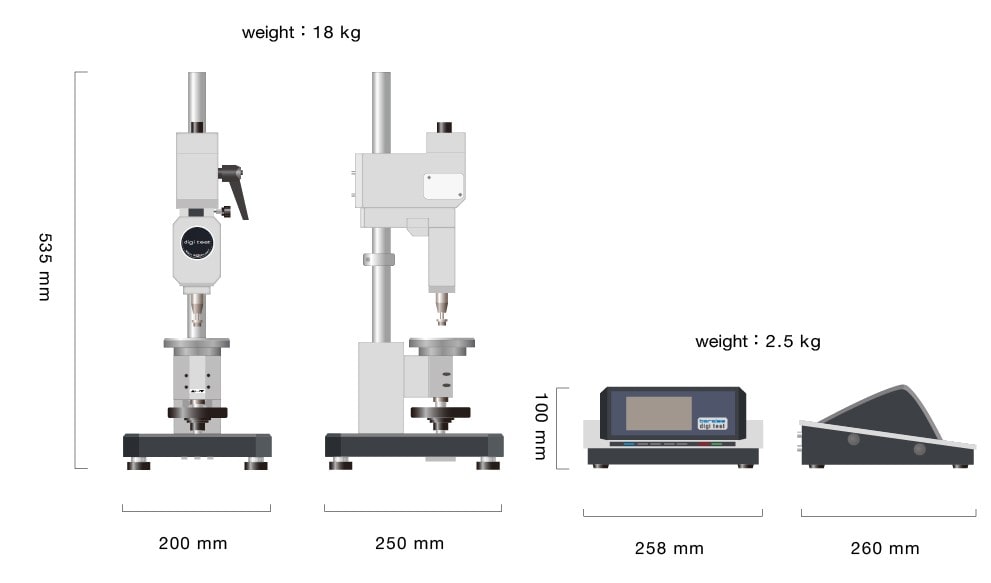

The Bareiss digi test II Gelomat is a fully automatic and modular digital hardness tester commonly used by many of the leading pharmaceutical vitamin and even paintball companies around the world. In today’s increasingly interconnected and highly regulated global markets, adherence to ‘critical-to-quality’ attributes is required to deliver best-in-class products. To prevent defective capsules from reaching the market, these companies are relying on our capsule hardness tester digi test II Gelomat to apply a compressive force to the gelatin capsules to confirm they have sufficient wall strength to withstand external forces during manufacturing, storage, packaging, transport, and finally when used by a consumer.

Features and Benefits:

1) User-Friendly: This automatic shore hardness tester is equipped with an electronic unit that can show user information, time, and method of measurement, and is equipped with various other configurations along with automatic measurement of time and range detection.

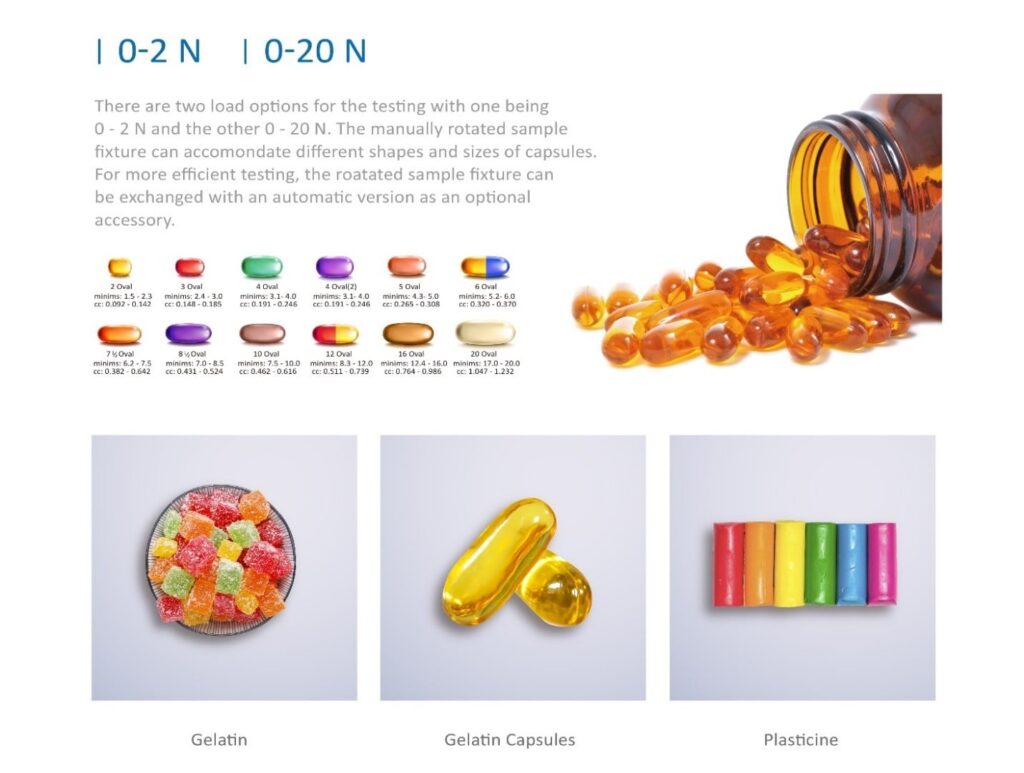

2) Mechanism: The measuring devices (0-20N & 0-2N) have an easy plug-and-play solution with no complex mechanism. The measuring devices can easily be fastened by hand using the knurled nut and the electronic unit can easily detect the device once it is set up.

3) Complexity: Gelatin capsules of different shapes can easily be tested using different manual & automatic fixtures.

4) It is FDA 21 CFR Part 11 compliant and comes with a 3-Q validation report ready as requested by customers.

Operating Procedure:

1) The electronic unit is switched on and the additional weights are loaded on the pickup bracket for the measuring load of range 0-20 N and no additional load is required for the measuring load of 0-2N.

2) For Gelatin capsules centrofix fixture is used on the supporting table. Care must be taken to align the centrofix parallel to pick up bracket which is tightened with the help of knurled screws.

3) The distance between the indenter and the centrofix should be adjusted up to 10 mm by loosening the clamping lever of the pickup bracket and pushing down carefully unit this distance is reached.

4) The counter nut is loosened, and the knurled nut is rotated until the indenter is in the center of the template.

5) The measurement is started by pressing the ‘Start’ button on the electronic unit and the measuring device is lowered onto the capsule automatically.

6) After reaching the activated lift the measuring device moves back to its initial position. The recommended lift is 2.0 mm.

7) The measured value is shown on the display and is transferred via the interface at the same time.