Product Information:

HP Analog Durometer | Digital Shore Durometer Hardness Tester | Rubber & Plastic Hardness Tester

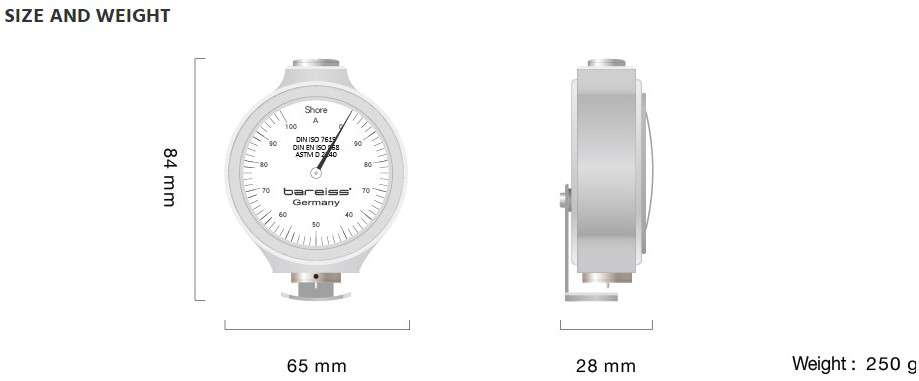

Introducing the Bareiss HP analog durometer shore hardness tester – the ultimate solution for reliable and durable durometer testing. Since its initial manufacture in 1954, the HP durometer shore hardness tester has been widely regarded as the industry standard, consistently delivering exceptional results. Crafted from high-quality aluminum, the entire chassis of the HP durometer shore hardness tester is not only lightweight, but also incredibly durable, making it a preferred choice for businesses seeking a compact and long-lasting device. With a unique mechanism that utilizes different-sized ball bearings, the HP durometer shore hardness tester ensures smooth movement of the indenter, without any friction. Additionally, the HP durometer shore hardness tester is equipped with a customizable presser foot, providing flexibility to suit varying testing requirements. Choose the Bareiss HP analog durometer for superior performance and long-lasting durability.

Features and Benefits:

1) User Friendly: Our rubber and plastic hardness tester the HP Analog Durometer is compact and lightweight making it more durable and easier to carry in the field.

2) Special Feature: The rubber and plastic hardness tester the HP Analog Durometer reduces friction during travel of the indenter to achieve the best measuring results.

3) Accuracy: The Analog Shore Durometer hardness tester can achieve 0.5 units of shore compared with the allowable tolerance of ±1.0 units of shore prescribed by the standards.

4) The Analog Durometer rubber and plastic hardness tester is widely available in different scales.

Operating Procedure:

1) Hold this rubber and plastic hardness tester the HP durometer firmly and press it onto the specimen vertically until the circular presser foot is in full contact with the specimen. Take the reading after 3 seconds.

2) The room temperature and the contact pressure should refer to the corresponding standards and be recorded accordingly.

3) During the measuring, try not to tilt or move the shore durometer hardness tester. The measuring time can be extended to 15 seconds if the specimen material is non-homogenous.

4) The test result could be unreliable if the shore durometer hardness tester presser foot is not parallel to the specimen during the measuring process.