Product Information:

Hardness Tester | Paper Drum Tester | Rubber Roller Hardness Tester

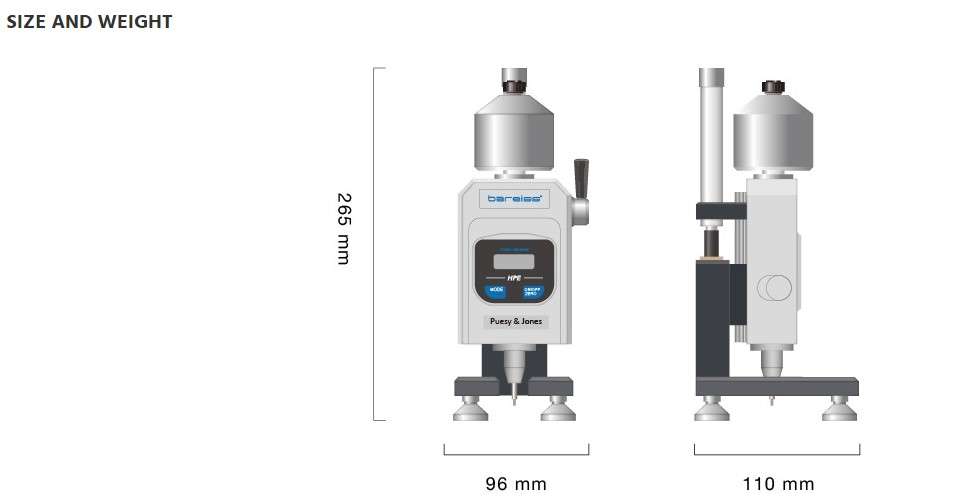

Discover the HPE II Pusey & Jones digital hardness tester, paper drum tester and rubber roller hardness tester – the go-to solution for the paper and rubber industries. This rubber hardness tester’s unparalleled testing ability enables the measurement of hardness for curved shaped and cylindrical specimens, making it a preferred choice among rubber and paper industry professionals. With the rubber hardness tester’s integrated test stand and adjustable base, the HPE II provides accurate and precise measurements of hardness. Additionally, this rubber hardness tester’s remarkable memory can store up to 300 measured values, ensuring seamless tracking and analysis of testing data. Trust in the HPE II Pusey & Jones digital hardness tester for exceptional performance and reliable results on rubber & elastomer materials e.g. rubber rollers, standard blocks made of rubber and paper rollers.