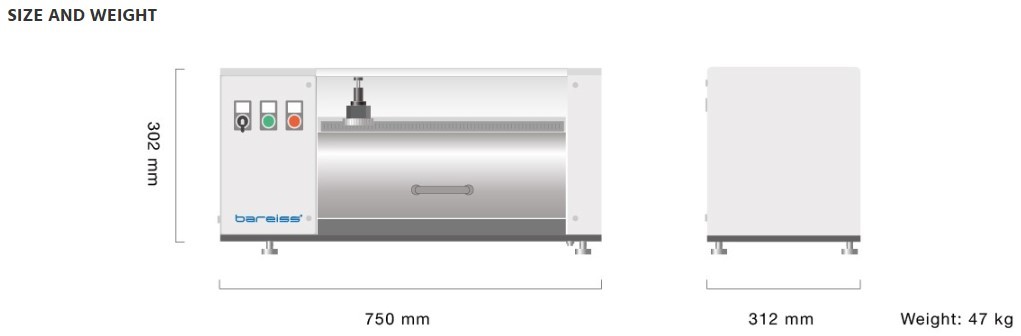

Product Information:

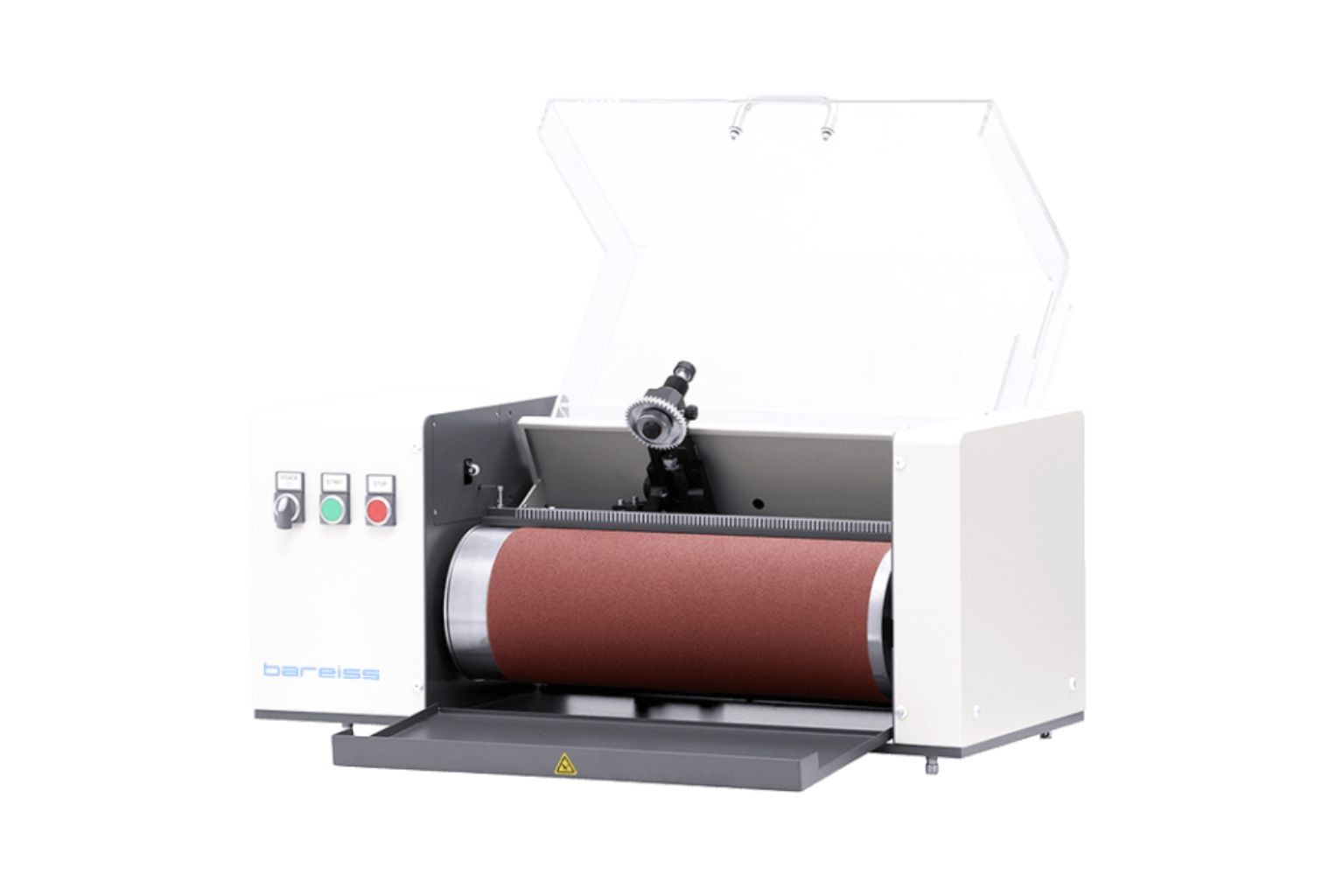

Abrasion Tester

Abrasion Testing involves the determination of volume loss due to the abrasive against a test piece when it rubs over a specified grade of abrasion paper. To evaluate the abrasion resistance of rubber materials like, tires, conveyor belts, automotive belts, hoses, footwear, or a multitude of other products , we need to test them under abrasive conditions. The actual performance of rubber products during their performance cycle cannot always be predicted and therefore our rubber hardness abrasion testing instrument the Abrasion Tester acts as the auxiliary testing equipment for standard determination of the hardness of elastomers against abrasion.

Operating Procedure:

1) The abrasion tester is switched on with the POWER rotary switch and the protective hood is opened.

2) The test piece is fixed on the sample holder and the protective hood is closed.

3) The automatic standard abrasion process can be interrupted any time by pressing the STOP button.

4) Start the abrasion process with the START button.

5) After the set abrasion path is traversed, the abrasion tester is switched off automatically, and the protective hood is opened.

6) The sample is taken out from the sample holder is bought back to its base position and the protective hood is closed.

7) Switch off the abrasion tester with the POWER rotary switch after reaching the activated lift and finally, the measuring device moves back to its initial position. The recommended lift is 2.0 mm.