What is a Hardness Test?

In various industries, a hardness test is a testing method performed to measure a material’s hardness, strength, flexibility, and wear resistance. Hardness testing is performed during the quality control process to ensure the material meets the standards.

What is a Shore Durometer?

A Shore durometer is an instrument used to measure the hardness of different materials such as soft rubber, elastomers, natural rubber products, neoprene, casting resin, polyester, soft PVC, leather, pressure rollers, hardboards, wood, and more.

What is Shore Durometer Hardness Testing?

The Shore durometer is an internationally recognized measurement standard for hardness testing. Shore durometer testing is a standardized way to measure the hardness of polymeric materials, including plastics and rubber. Shore durometer testing determines a material’s hardness value or resistance to indentation by penetrating an indenter into the test sample. Shore hardness is expressed by a number ranging from 0 to 100 on a Shore durometer scale. Higher numbers indicate more resistance to indentation. The higher the number on the scale, the harder the material. Lower numbers mean less resistance, thus, softer materials. Shore “A” scale durometers are used for more delicate materials, and Shore “D” are used for hard materials. Other scales are available but less commonly used.

Which Shore Durometers offer the Highest Precision in the Market?

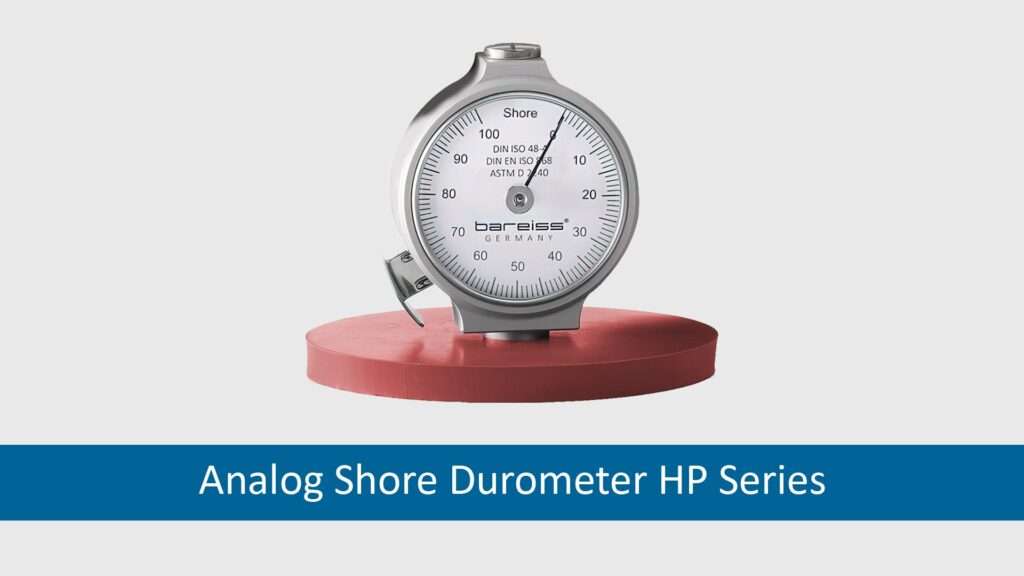

The HP Analog Shore Durometer hardness tester has been the most popular hardness testing instrument, selling over half a million units worldwide. Our Evergreen HP Analog Durometer hardness tester is nearly identical to the first model made in 1954. The shore durometer measures the depth of an indentation in the material created by a given force on a standardized presser foot. This depth depends on the material’s hardness, viscoelastic properties, presser foot’s shape, and the test’s duration. To avoid the indenter from traveling with friction, we combined different size bearing balls to create smooth traveling for the indenter.

Analog Durometer HP Series l Shore Hardness Tester

The entire chassis of the HP Analog Shore Durometer is made of aluminum, providing lightweight and durability. This Shore Durometer hardness tester’s great advantage is the precise indication of its measured values. The HP Analog Durometer hardness tester can be used as a portable instrument or with the tabletop test stand. Bareiss’ HP durometer series is available in different shore and non-shore scales and with the possibility of a customized presser foot to suit different requirements.

Hardness Tester Calibration Services

Every unit of the Analog Durometer is carefully assembled and calibrated by the Bareiss technicians. When a measuring instrument is being calibrated, the given deviation is determined by various measurements versus standard references. A calibration certificate is then issued indicating the measuring results and the corresponding measurement uncertainties and the instrument is marked as calibrated. All documents together with the calibration certificate provide traceability of national standards. Check out our DAkkS/DKD calibration certificate – Sample

Hardness Testing Instrument’s Experts

For over 65 years, Bareiss has produced a variety of hardness testing instruments. Our wide range of material testing equipment is used in the food, pharma, plastics & elastomers industries. We serve from several locations worldwide, including Germany, Canada, China, and Taiwan. Quality has always been one of the essential pillars of Bareiss; thus, our testing instruments are engineered and manufactured in Oberdischingen, Germany. Even raw materials are brought into the production building and are machined in-house. Over the years, Bareiss has successfully served customers such as:

– Proctor & Gamble

– Adidas

– Pirelli and Goodyear

– Apple

– Samsung

– Huawei

– Infineon

– BMW

– Porsche

– Suzuki

– Audi

– Rolls-Royce & Many More!

Feel free to Request a Quote for any Shore durometer hardness tester and we will be happy to assist. At Bareiss, it’s our pleasure to enhance your product quality with our advanced material testing instruments!