Digi test Easy | IRHD M

Hardness testing device for the “IRHD Micro” method, used for testing the hardness of rubber, plastic, and all elastic materials with a minimum material thickness of 1.5 mm, in accordance with DIN ISO 48-2.

Our user-friendly hardness tester digi test Easy offers you the opportunity to perform fully automated hardness tests using the IRHD M testing method. The digi test Easy | IRHD M combines the attractive price of the IRHD Compact with the comfort and automation of the digi test II.

The extremely easy operation of the digi test Easy allows you to quickly measure your test specimens according to IRHD M. Obtain your measurement result with just the push of a button. In combination with the manually available Barofix accessory, this is the perfect entry-level model for hardness testing of O-rings.

Key Features and Benefits:

1: For your entry into IRHD hardness testing The digi test Easy is the ideal entry-level model into the world of IRHD measurement. With its hassle-free setup and an easy-to-use testing process, hardness testing can be effortlessly performed on your desired samples.

2: Proven technology – Made in Germany since 1954 The digi test Easy combines the attractive price of the IRHD Compact with the comfort and automation of the digi test II – reliable and user-friendly.

3: Perfect accessory for measurements on O-rings In combination with the manually available Barofix accessory, the digi test Easy is the perfect entry-level model for hardness testing of O-rings. The Barofix is a manual positioning device for centering O-rings and is available for various sizes of O-rings.

4: Minimal shipping effort for annual calibration To ensure accurate measurements, we recommend annual calibration in our DAkkS-accredited laboratory. For calibration, you only need to send us the core component of the digi test Easy, the measuring device. This means minimal effort for you: simply send in the measuring device of the digi test Easy, and we’ll take care of the rest – quickly, reliably, and without hassle.

5: With the free software tool “BareissOne QuickMeasure” The free software tool “BareissOne QuickMeasure” allows you to easily capture, print, and export your data in just a few simple steps.

6: Everything from a single source From development and manufacturing to maintenance and accredited calibration of our devices – as a manufacturer and accredited calibration laboratory, we provide you with comprehensive solutions and services in the field of hardness testing, all with the best quality from a single source.

Sample geometry

- O-rings

- Sheet material with a material thickness of at least 1.5 mm

- Molded parts

Technical Specifications

| Test Stand with Mounting Arm and Measuring Device |

| Dim. W x H x D: |

min. 20 x 55 x 25 cm

max. 20 x 60 x 31 cm |

| Electronic Unit |

| Dim. W x H x D: |

min. 26 x 11,5 x 26,5 cm

max. 26 x 11,5 x 34 cm |

| Total weight: 14 kg |

| Voltage: |

100 – 250 VAC |

| Current: |

2 A |

| Frequency: |

50 / 60 Hz |

| Protection Class: |

IP 30 |

| Interface |

| USB or RS-232 interfaces for data transfer |

| Enviromental conditions |

| USB or RS-232 interfaces for data transfer |

Scope of delivery

| Test stand |

| Mounting arm for measuring units |

| Electronic unit |

| USB data cable |

| Operating manual |

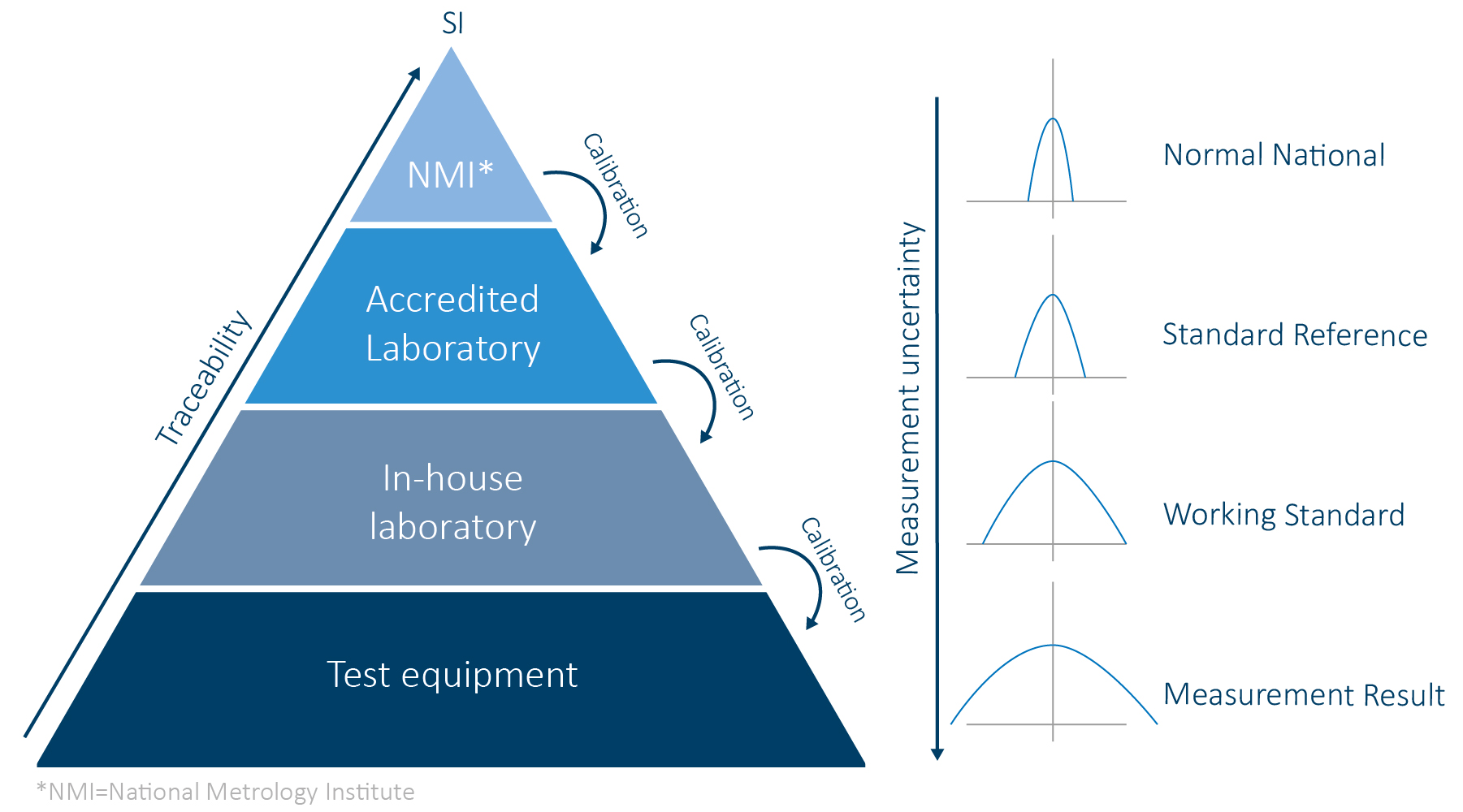

Traceability

Traceability refers to the ability to monitor the origin, progress and history of our products, calibrations, processes, or measurements. This means that all steps and parameters that contribute to the creation of our products must be documented and traceable.

Traceability ensures the transparency, integrity and reliability of data and enables the checking of quality standards. It plays a crucial role in error detection, quality control and ensuring compliance with legal requirements and our quality standards.

Automatic Shore hardness testing for ASTM D2240 compliant samples

HPE III shore durometer attached to an Automatic test stand

HPE III shore durometer attached to a Manual test stand

HPE III shore durometer attached to a Steering Wheel